Ground Run-up Enclosures | GRE's

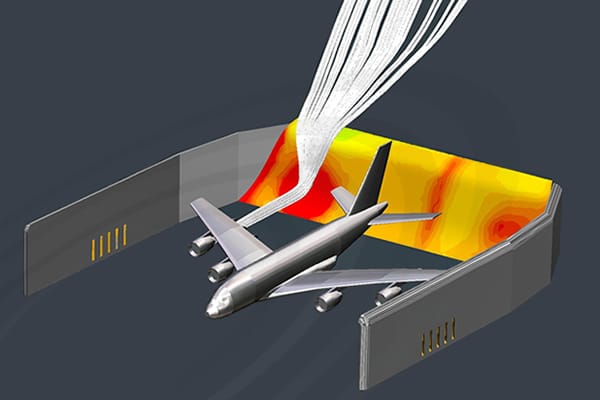

The Ground Run-up Enclosure (GRE) is a combined acoustic and jet blast protection structure that allows aircraft engine testing either for first engine runs after manufacture or post maintenance activities for MRO’s or airlines.

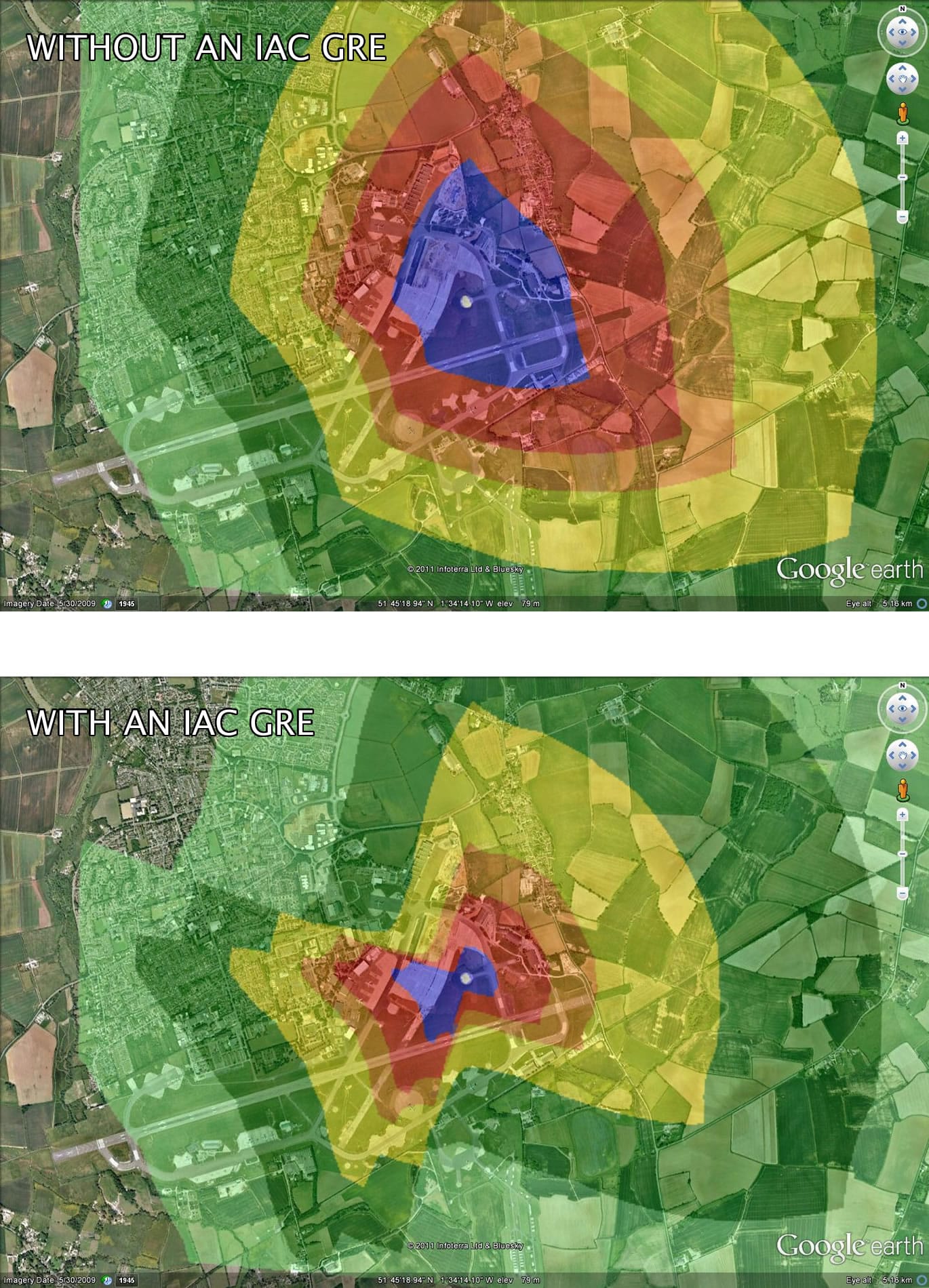

The dual function provides acoustic benefits of up to 20dB(A) by providing noise absorption and blocking the transmission of noise directly to noise sensitive locations while incorporating jet blast protection built into the rear wall structure.